How Vibratory Bowl Feeders Are Revolutionising the Manufacturing Industry

In the fast-paced world of modern manufacturing, automation is the key to staying competitive, improving efficiency, and ensuring consistent quality. Among the many innovations driving this transformation, vibratory bowl feeders stand out as a game-changing technology. These compact, efficient, and versatile systems are reshaping how manufacturers handle parts and components during the assembly process. From automotive to electronics, vibratory bowl feeders are helping businesses streamline operations, reduce costs, and boost productivity.

But what exactly is a vibratory bowl feeder, and why has it become so indispensable in today’s manufacturing landscape? Let’s explore how these systems work and why they are revolutionising the manufacturing industry.

What Is a Vibratory Bowl Feeder?

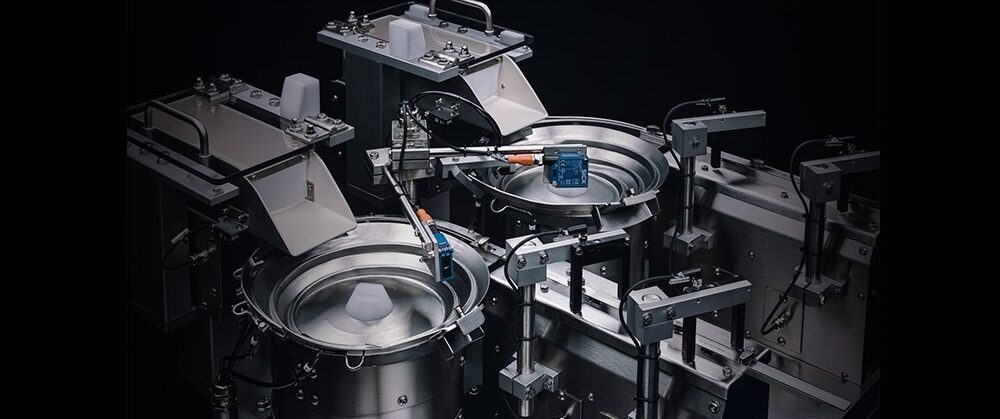

A vibratory bowl feeder is a type of automated system designed to orient and feed small parts or components into a production line or assembly station. The system typically consists of a bowl (usually made of stainless steel) that vibrates in a controlled manner. This vibration causes the parts to move along a specific path, which is often designed to orient them in a specific direction for automated assembly or further processing.

The vibratory motion is created using electromagnetic coils that generate a wave-like motion, making the parts move up a spiral track or chute. Depending on the design, bowl feeders can also be equipped with additional features such as air jets, sensors, or camera systems to further guide and inspect parts as they are fed into the line.

RNA bowls feed and orientate your products carefully, at the same time guaranteeing a consistent and accurate flow of components into your production machinery.

Why Are Vibratory Bowl Feeders So Important?

Vibratory bowl feeders are playing an increasingly critical role in the manufacturing industry for several reasons:

1. Increased Speed and Efficiency

Manual feeding and sorting of parts can be slow, labour-intensive, and error-prone. Vibratory bowl feeders automate this process, significantly increasing the speed at which parts are delivered to the assembly line. This not only reduces the time spent on feeding but also minimises the risk of human error. Parts are fed at a controlled rate, allowing for more consistent throughput and helping to keep up with the demands of high-volume production.

2. Improved Precision and Accuracy

One of the key advantages of vibratory bowl feeders is their ability to orient and position parts with incredible precision. Parts can be fed into an assembly line in a uniform direction, reducing misalignments or delays caused by incorrect placement. This precision ensures that machines or robots can handle the parts without the need for manual adjustments, leading to a higher level of automation and fewer production interruptions.

3. Cost Savings

Though vibratory bowl feeders come with an initial investment cost, their long-term benefits far outweigh the expense. By eliminating the need for manual labour, reducing part handling time, and minimising errors, manufacturers can save on labour costs, reduce material waste, and improve overall production efficiency. Moreover, because they can run 24/7 without breaks, bowl feeders help businesses meet tight production deadlines, further enhancing cost-effectiveness.

4. Versatility Across Industries

From small components like screws, washers, and nuts to larger, more complex parts, vibratory bowl feeders are highly versatile. Their flexibility makes them suitable for a wide range of industries, including:

- Automotive: Bowl feeders are used to feed everything from screws and nuts to complex components for automotive assembly.

- Electronics: Small parts like microchips, resistors, and capacitors are oriented and fed for assembly in high-precision electronics manufacturing.

- Pharmaceutical: In pharmaceutical production, bowl feeders are used to handle delicate pills, vials, and other small items in a contamination-free environment.

- Food & Beverage: In food processing, bowl feeders handle items like caps, lids, and packaging materials, ensuring hygiene and efficiency.

5. Customisable Designs for Specialised Needs

Vibratory bowl feeders are highly customisable. Manufacturers can design systems tailored to their specific needs, whether that’s for feeding fragile parts, handling parts with specific sizes or shapes, or accommodating unique materials. Bowl feeders can also be designed with specific orientations and speeds to match the exact requirements of the production process. This flexibility allows manufacturers to handle a variety of parts with different physical characteristics, making it an invaluable solution for both mass production and niche manufacturing needs.

6. Enhanced Quality Control

With vibratory bowl feeders, quality control becomes an integral part of the assembly line. Many modern systems are equipped with integrated sensors or camera systems that can detect defects, misaligned parts, or foreign contaminants in real time. This immediate feedback ensures that only high-quality parts make it to the next stage of production, reducing the likelihood of defects and improving the overall quality of the finished product.

7. Reduced Downtime and Maintenance

Another significant benefit of vibratory bowl feeders is their reliability and minimal downtime. When properly maintained, these systems can run continuously for long periods without requiring much attention. The maintenance is relatively straightforward, typically involving cleaning and occasional adjustments to ensure optimal performance. The reduced need for manual intervention and the long operational life of these systems contribute to a more streamlined production process.

The Future of Vibratory Bowl Feeders in Manufacturing

As manufacturing continues to evolve, the role of vibratory bowl feeders is expected to grow. Advances in automation, robotics, and artificial intelligence (AI) will only further enhance the capabilities of these systems. For example:

- Smart Bowl Feeders: Future developments may include smart bowl feeders equipped with sensors and AI that can learn to adjust to new parts and configurations automatically, reducing the need for reprogramming or manual intervention.

- Integration with Robotics: As robots become more advanced, vibratory bowl feeders will continue to work in harmony with robotic arms and vision systems, enabling seamless and fully automated production lines.

- Sustainability: As industries look for ways to reduce waste and improve sustainability, vibratory bowl feeders will likely see innovations in energy efficiency and eco-friendly materials.

Vibratory bowl feeders are no longer just a luxury in the manufacturing industry; they have become a necessity. By offering increased efficiency, precision, and cost-effectiveness, they are helping businesses improve production times, reduce waste, and meet the demands of an increasingly fast-paced market.

As automation continues to shape the future of manufacturing, vibratory bowl feeders will play an even more central role in helping industries deliver high-quality products with greater speed and efficiency. For more information, contact RNA for market-leading solutions in vision systems, automated feeding & handling & robotic systems.

Source: How Vibratory Bowl Feeders Are Revolutionising the Manufacturing Industry